In the realm of manufacturing, precision is paramount. From aerospace components to medical implants, industries demand intricate parts that meet exacting specifications. This is where 5-axis CNC machining services shine. Leveraging advanced technology, these services offer unparalleled precision and versatility, revolutionizing the manufacturing landscape. Let’s delve into the art of precision through mastering 5-axis CNC machining services.

Understanding 5-Axis CNC Machining

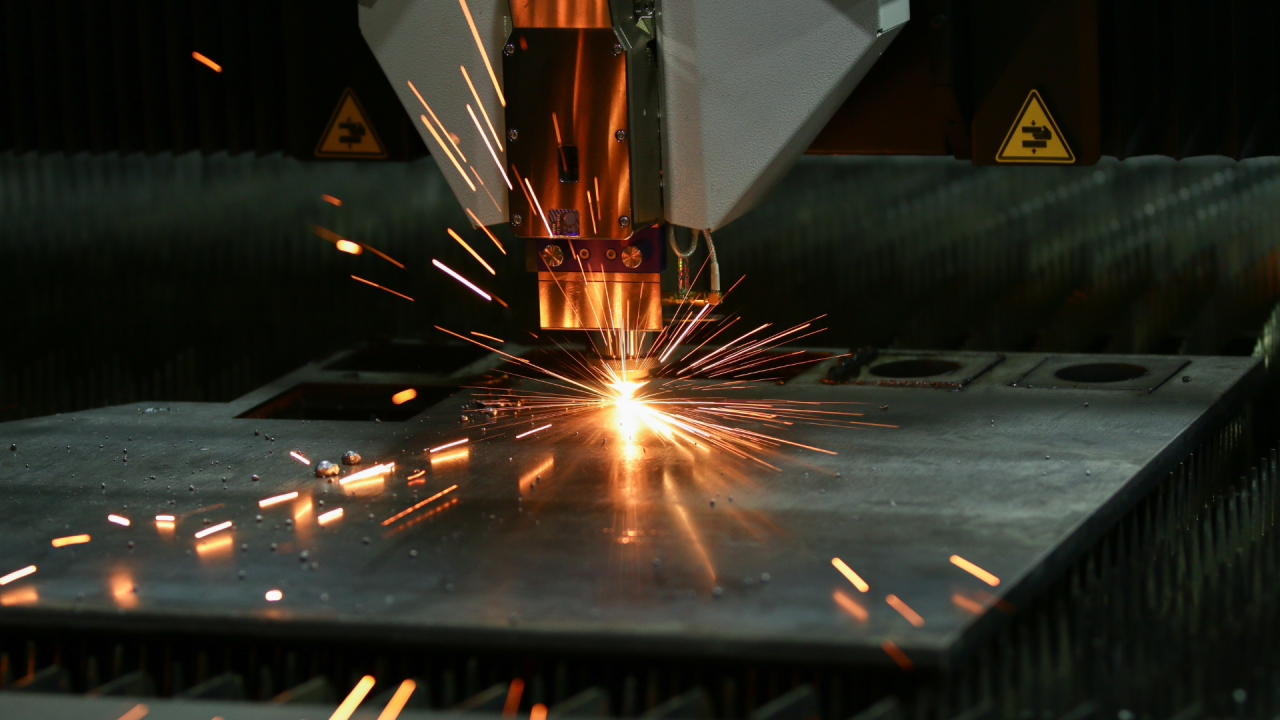

Traditional machining techniques are often limited by their ability to access certain angles and surfaces. Enter 5-axis CNC machining, a game-changer in the manufacturing industry. Unlike its 3-axis counterpart, which operates on three axes (X, Y, and Z), 5-axis machining adds two rotational axes, allowing for complex geometries and intricate designs to be realized with utmost precision.

Unrivaled Precision

The hallmark of 5-axis CNC machining is its ability to achieve unparalleled precision. By utilizing simultaneous movement along five axes, manufacturers can access virtually any angle or surface with ease. This precision is invaluable in industries where even the slightest deviation can lead to catastrophic consequences, such as aerospace or medical manufacturing. Whether it’s crafting turbine blades with aerodynamic perfection or sculpting intricate medical implants, 5-axis CNC machining ensures that every 5 axis cnc machines is executed with the utmost accuracy.

Enhanced Efficiency

Beyond precision, 5-axis CNC machining also offers enhanced efficiency. With the ability to access multiple sides of a workpiece in a single setup, machining time is significantly reduced compared to traditional methods. This not only improves productivity but also reduces the risk of errors associated with multiple setups. Moreover, the seamless integration of CAD/CAM software further streamlines the process, allowing for rapid prototyping and iterative design improvements without sacrificing precision.

Versatility in Design

One of the most compelling aspects of 5-axis CNC machining is its versatility in design. Complex geometries that were once deemed impossible or impractical to manufacture are now within reach. From freeform surfaces to undercut features, 5-axis machining empowers designers to push the boundaries of what’s possible. This flexibility not only fosters innovation but also enables the creation of highly customized parts tailored to specific applications. Whether it’s optimizing airflow in automotive components or maximizing strength-to-weight ratios in aerospace structures, the design possibilities are limitless.

Optimized Material Usage

Precision isn’t just about achieving tight tolerances; it’s also about maximizing material efficiency. 5-axis CNC machining excels in this regard by minimizing waste through optimized tool paths and reduced setup requirements. By precisely sculpting parts with minimal excess material, manufacturers can minimize scrap and maximize yield, resulting in cost savings and environmental benefits. This level of efficiency is especially critical in industries where materials are scarce or expensive, such as aerospace or medical device manufacturing.

Challenges and Considerations

While 5-axis CNC machining offers a multitude of benefits, it’s not without its challenges. The increased complexity of programming and setup requires skilled operators and sophisticated software tools. Moreover, maintaining tight tolerances across multiple axes demands meticulous attention to detail and rigorous quality control measures. Additionally, the initial investment in equipment and training can be substantial, making it imperative for manufacturers to carefully evaluate the cost-benefit ratio before adopting 5-axis machining capabilities.

The Future of Manufacturing

As technology continues to evolve, so too will the art of precision machining. The rise of additive manufacturing and advancements in automation are poised to further revolutionize the industry, offering new possibilities for design optimization and production efficiency. However, amidst these innovations, the timeless pursuit of precision will remain paramount. Whether it’s crafting intricate components for next-generation aircraft or revolutionizing medical treatments through personalized implants, mastering the art of precision will continue to drive progress in manufacturing for years to come.

Conclusion

In a world where precision reigns supreme, 5-axis CNC machining services stand at the forefront of manufacturing innovation. With their unrivaled precision, enhanced efficiency, and versatility in design, these services empower industries to push the boundaries of what’s possible. While challenges abound, the rewards of mastering the art of precision are undeniable, paving the way for a future where precision is not just a goal but a standard.

Top of Form