In the realm of automotive aesthetics, wheel customization has long been a hallmark of personalization and style. The evolution of technology in this field has paved the way for innovative methods, and one such groundbreaking approach is Computer Numerical Control (CNC) machining. The future of wheel customization appears increasingly promising as CNC machining techniques continue to revolutionize the way wheels are designed, manufactured, and customized.

Advancements in CNC Machining

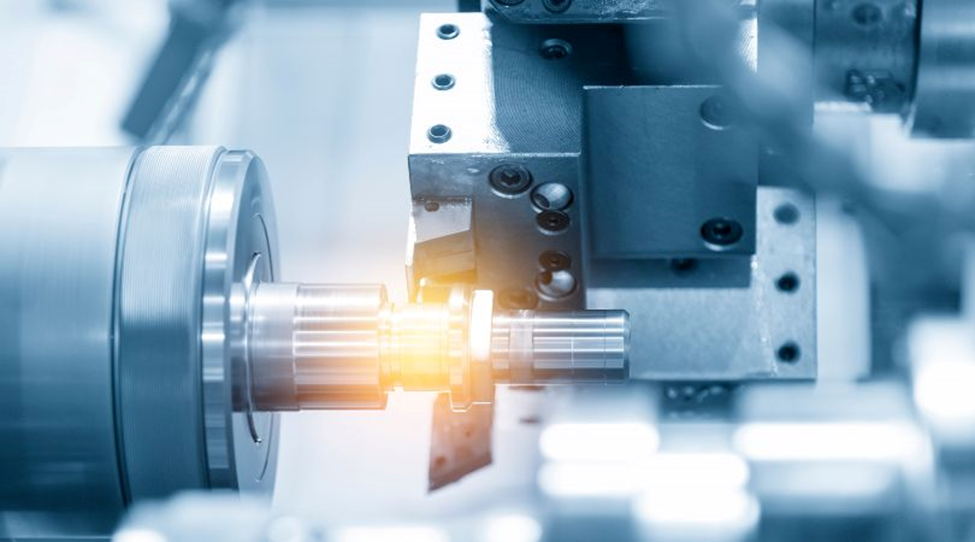

CNC machining has emerged as a game-changer in wheel customization due to its precision, efficiency, and flexibility. Unlike traditional methods that relied heavily on manual labor and limited design options, CNC machining utilizes computer-controlled machinery to carve intricate designs with unparalleled accuracy.

The use of CAD (Computer-Aided Design) software allows enthusiasts and designers to create highly detailed and complex wheel designs. These designs are then translated into custom wheel machining instructions for CNC machines, enabling the creation of customized wheels that meet the exact specifications of the designer.

Personalization and Tailored Designs

One of the most significant advantages of CNC machining in wheel customization is the ability to offer unparalleled personalization. Enthusiasts can now explore a vast array of design possibilities, from intricate patterns and unique textures to personalized engravings or logos on their wheels.

CNC machining enables the realization of individualized visions, empowering car owners to express their personality and preferences through their vehicle’s wheels. Whether it’s a sleek and modern design or a more elaborate and artistic approach, CNC machining facilitates the production of tailored designs that cater to diverse tastes and styles.

Material Innovation and Strength Optimization

Beyond design flexibility, CNC machining allows for the utilization of various materials to craft wheels. From aluminum and steel to high-performance alloys and composite materials, manufacturers can experiment with different materials to enhance both aesthetics and performance.

Moreover, CNC machining enables the optimization of wheel strength and durability. By precisely carving materials and implementing innovative structural designs, engineers can create wheels that offer superior strength while maintaining a lightweight profile. This balance between strength and weight is crucial for enhancing overall vehicle performance, including handling, acceleration, and fuel efficiency.

Streamlined Production and Efficiency

The integration of CNC machining in wheel customization streamlines the production process, reducing lead times and minimizing material waste. Compared to traditional manufacturing methods that often involved multiple steps and manual labor, CNC machining offers efficiency and consistency in production.

Furthermore, CNC technology allows for quick prototyping and modifications, facilitating a faster turnaround for custom designs. This rapid iteration process enables designers and manufacturers to refine their concepts swiftly, ensuring that the final product meets the customer’s exact specifications.

Environmental Sustainability

In addition to its efficiency benefits, CNC machining aligns with the growing emphasis on environmental sustainability in the automotive industry. The precise nature of CNC manufacturing significantly reduces material wastage compared to conventional methods, contributing to a more eco-friendly approach to wheel customization.

Moreover, the ability to create lightweight yet robust wheels aids in improving a vehicle’s fuel efficiency, subsequently reducing its carbon footprint. As environmental concerns continue to drive innovation across industries, CNC machining offers a promising avenue for more sustainable automotive practices.

Conclusion

The future of wheel customization is undeniably intertwined with the advancements in CNC machining technology. The fusion of design creativity, material innovation, precision manufacturing, and environmental consciousness positions CNC machining as a pivotal force in shaping the next generation of customized wheels.

Enthusiasts can anticipate a future where the boundaries of wheel design are continually pushed, offering endless possibilities for personal expression and performance enhancement. As CNC machining continues to evolve and become more accessible, the automotive world is poised to witness a renaissance in wheel customization, catering to the diverse tastes and preferences of car enthusiasts worldwide.