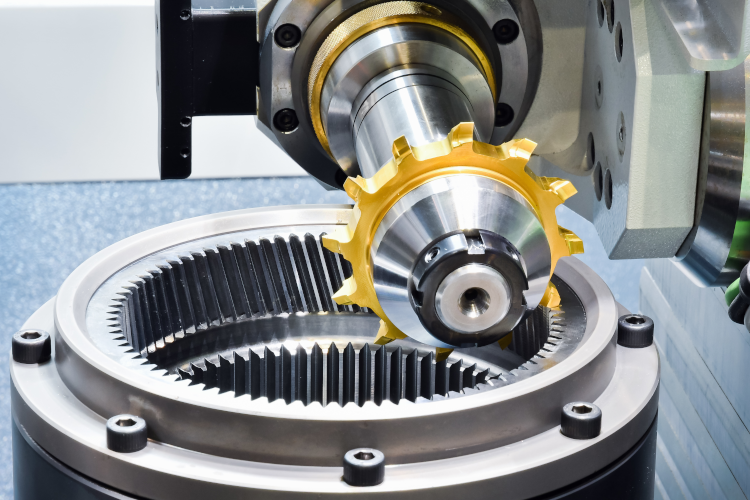

Gear-cutting tools manufacturers have practical experience in delivering high-accuracy tools utilized in the assembling of gear wheels for different businesses, including automobile, aviation, and large equipment. The gear cutting tools like hobs, shapers, and broaches from these manufacturers are designed to be long-lasting, accurate, and effective. To guarantee optimal performance, they use cutting-edge materials and technology and provide individualized solutions to meet specific client requirements, increasing production efficiency and gear quality.

Meeting Fundamental Industry Needs

Gear-cutting tools are imperative in the development of gear, which are vital parts of numerous mechanical frameworks. Gears are the foundation of movement and power transmission in industrial machines, automotive transmissions, aerospace turbines, and other applications. Manufacturers of gear cutting tools play a crucial role in providing these industries with the precise tools necessary to produce dependable gears. Manufacturers are indispensable in the global supply chain because they contribute to the smooth operation of various industries by providing these essential tools.

High Demand and Market Stability

There is always a constant and steady demand for gears and therefore, for the gear cutting tools, around the globe. Car and aviation for instance continue to grow and improve the need for advanced gears increases as enterprises. EVs, sustainable power arrangements, and headways in present-day mechanization urgently need enhanced gears, inevitably motivating the need for state-of-the-art gear-cutting appliances. This makes a stable and generating business sector for producers, which negates business viability in the long term.

Opportunities for Technological Innovation

The production of gear cutting tools manufacturers india is a highly technical field with significant innovation potential. Producers get the opportunity to foster new materials, plans, and assembling processes that can upgrade the exhibition of gear-cutting apparatuses. Advancements could incorporate the utilization of cutting-edge coatings to expand apparatus life, the improvement of new device calculations for more proficient cutting, or the fuse of savvy innovations for better process control.

Trade Potential and Worldwide Reach

The particular concept of gear-cutting tools very much means that there is often a need for good products beyond limited consumption. Manufacturers can seize logical open entryways, getting to the customer in countries where it is impractical or extraordinarily hard to build up such machines physically. Manufacturers can thus, increase their sales to the international market, and lead to diversification of the manufacturing company’s revenue base and hence, minimize their openness to fluctuations in the domestic market if they establish credibility for quality and reliability.

Sustainability and Long-Term Viability

Gear-cutting tool manufacturers have a chance to make a difference as industries move toward more environmentally friendly practices by creating tools that make gear production more efficient and last longer. By focusing on manageable assembling practices like lessening waste, further developing energy effectiveness, and utilizing eco-accommodating materials manufacturers can fulfill the developing need for naturally mindful products.

Bottom Line

Gear-cutting tool manufacturers assume a vital part in the accuracy designing industry by giving fundamental apparatuses that drive proficiency and exactness in gear creation. Gear components are guaranteed to meet stringent performance standards credit to their dedication to high-quality materials, cutting-edge technology, and custom solutions. By ceaselessly propelling their items and administrations, these makers support the development and advancement of different areas dependent on solid and exact gear mechanisms.